Add to Cart

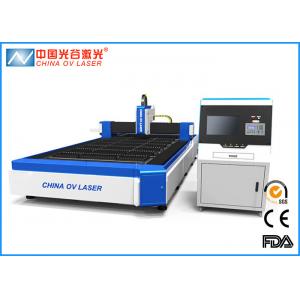

Kitchenware Laser Sheet Metal Cutting Machine Raycus Fiber 500W 2mm

1. The cutting quality is good:

Because of the small laser spot, high energy density, fast cutting speed, laser cutting can therefore get better cutting quality.

(1) Cutting knife is narrow and parallel on both sides, also perpendicular to surface, dimensional accuracy of cutting pieces can be up to + / - 0.05 mm.

(2) Cutting surface is smooth and beautiful, the surface roughness is only a few dozen microns, laser cutting can be used as the final working procedure, parts can be even used directly without mechanical processing.

(3) Heat affected zone is very small, material performance is hardly affected near the kerf width , and the workpiece deformation is small. Also, kerf geometry is good , slitting rectangular cross-section shapes appear to be regular.

2. Highly automation:

Adopts digital control, you only need to use CAD to draw the picture and import to specialized software, laser cutting machine can cut out the artifacts you need, moreover there is intelligent typesetting function, thus can save raw material costs to the greatest extent.

3. High cutting efficiency:

Due to the transmission properties of laser, laser cutting machine has equipped with many sets of CNC work bench to realize numerical control. You only need to change the CNC program to cut different shape, as well as for two-dimensional cutting, and three-dimensional cutting.

4. Non-contact cutting:

There is no contact for work piece and laser head, so there is no tool wear. No need to change "tool" for different shapes parts processing, only need to change the output parameters. Laser, low noise, small vibration, and no pollution while cutting.

Machine Information

1. Cutting area: 1300x2500mm / 1500x3000mm / 2000x4000mm are optional

2. Laser source: Raycus laser generator (IPG or Nlight laser source are optional)

3. Laser head: Preste / Worthing / Empower / USA Lasermech / Germany Precitec are optional

4. Control system: Cypcut control system and software

5. Driver motor: Japan servo driver and motors

6. Drive system: 4 sets drivers, double big power drivers for Y axis

7. Reducer: Japan quality reducer

8. Water chiller: constant temperature control water chiller

Cutting Thickness

|

Material / Laser Power |

500W |

700W |

1000W |

1200W |

2000W |

|

Carbon Steel |

6mm |

8mm |

10mm |

14mm |

16mm |

|

Stainless Steel |

3mm |

4mm |

5mm |

6mm |

8mm |

|

Aluminum |

1mm |

3mm |

4mm |

5mm |

6mm |

|

Brass |

1mm |

2mm |

4mm |

4mm |

6mm |

|

Copper |

1mm |

2mm |

3mm |

3mm |

4mm |

|

Galvanized Steel |

1mm |

2mm |

4mm |

5mm |

6mm |

After-sale service

1. We provide 12 months warranty for the machine.

2. All extra parts for the machine can be purchased with agent price.

3. Email/ Skype/ MSN/ Trade manager online to support.

4. Life-long technical support and free after-sale service.

5. Professional technical team and salesperson help you with trouble shooting.

6. Free and professional training at our factory.

7. Door-to-door service if necessary.