Add to Cart

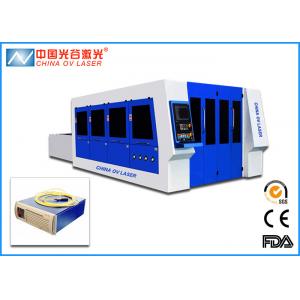

Fiber 7mm Sheet Metal Cutting Machine with 2000 x 4000 mm Working Table

Fiber Laser Cutting Sheet Metal Features:

(1) The quality fiber laser beam results in faster cutting speeds and higher quality cuts compared to other cutting solutions. The key advantage of a fiber laser is its short beam wavelength (1,064nm). The wavelength, which is ten times lower than that of a conventional C02 laser, generates high absorption into metals. This makes the fiber laser become a perfect tool for cutting sheets of stainless steel, mild steel, aluminum, brass, etc.

(2) The efficiency of a fiber laser far exceeds traditional YAG or CO2 laser equipment. The fiber laser beam is capable of cutting reflective metals with much less energy as the laser is absorbed into the metal being cut. The unit will consume little to no energy when not active.

(3) Another advantage of fiber laser is the use of highly reliable single emitter diodes with projected lifetimes greater than 100,000 hours of continuous or pulsed operation.

Technical Parameters:

| Laser Type: | IPG Fiber laser / Coherent fiber laser |

| Laser Power: | 700W / 1000W / 2000W |

| Working area: | 1500mmX3000mm / 2000mmX4000mm / 2000mmmX6000mm |

| Working Table Structure: | Fixed / Pallet Working Table |

| Control System: | PMAC full-closed loop servo control |

| Driving Mode: | Double ball screw driving / Double gear rack driving |

| Idle/Processing Speed: | 48m/min / 24m/min |

| Positioning Accuracy: | 0.05mm |

| Cooling System: | High precision constant temperature water chiller |

| Protection System: | Enclosure protection |

| Power Supply: | AC220V ± 5% 50 / 60Hz / AC380V ± 5% 50 / 60Hz |

| Total Power: | 7.5KW / 6KW~20KW |

| Support Format: | PLT, DXF, BMP, AI, DST, DWG, etc. |

| Floor Space: | 6.5mX3.2m (shuttle working table) |

Machine Features:

The double ball screw closed-loop system and imported open-type CNC system enable high processing accuracy and high working efficiency during high speed cutting.

Open structure is easy and convenient for material uploading and unloading.

Aiming at high speed cutting, we design and manufacture strengthened welded machine body after 2 times of aging process which ensures long-term accuracy and stability of performance.

Standard collocation of dual-pressure gas control system of 3 gas sources (high pressure air, nitrogen, oxygen) meets the processing requirement of all kinds of materials. Easy operation and low cost.

Standard collocation of automatic nesting software (including material management and optimized processing technology) and database of process parameters is provided for easy operation and simple management.

Optimized optical lens, specially designed nozzle and sensor technology realize smoother and more stable cutting.

Cutting Thickness:

500w: 3mm stainless steel,6mm carbon steel.

700w:4mm stainless steel, 8mm carbon steel

1000w:5mm stainless steel,10mm carbon steel

2000w:8mm stainless steel,15mm carbon steel

Application Industry:

Sheet metal, hardware, kitchenware, electronic, automotive parts, glass, advertising, craft, lighting,decoration,jewelry, etc.

Applicable Material:

Specially for carbon steel, stainless steel, galvanized steel, alloy, titanium, aluminum, brass, copper and other metal sheets.